- Статьи

- Science and technology

- Nanoprinting intelligence: new lithograph will help create artificial organs

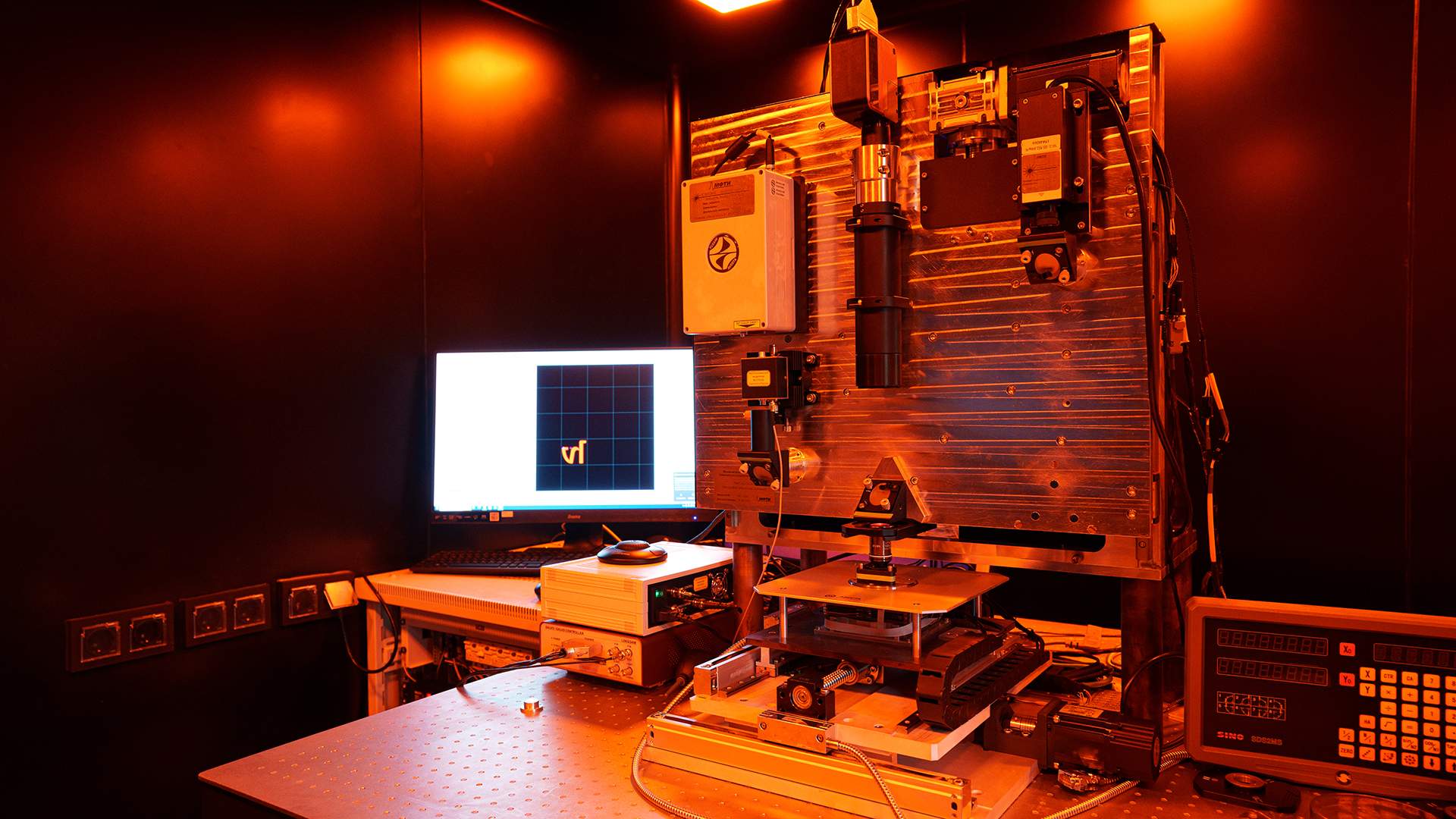

Nanoprinting intelligence: new lithograph will help create artificial organs

Russian scientists have developed a unique lithograph— a device for printing microstructures. These can be tiny mechanical devices, lenses, or filters that allow some types of cells to pass through and trap other types of cells. One of the most important applications of the development is frameworks for creating artificial organs and tissues. According to bioengineering experts, the quality of scaffolds and the matrixes on which they are grown greatly affects the properties of the final product. In addition, the lithograph is capable of bringing Russian photonics to a new level, experts say.

Printing with nanometer precision

MIPT scientists have developed a unique domestic lithograph for creating three-dimensional microstructures with a size of up to 150 elements and a resolution of 350 nanometers. These scales are quite enough, for example, to shoe a flea. With the help of the development, it is possible to print the smallest mechanical devices or frameworks for growing artificial biological organs with the desired geometry.

— To grow bioengineered objects, such as artificial organs, a skeleton system is first produced, on which cells capable of forming tissue are already applied. A special biocompatible polymer is used to produce the frame. Due to this design, we can arrange cells in a certain way so that they can better interact with proteins or other cells. This is important for growing various biological structures," said Danila Kolymagin, chief designer of the project and head of the Optical Lithography Design Bureau.

You can also use a lithograph to create miniature filters that can separate one cell from another. Thus, it is possible to isolate various components in biological substances or to separate healthy and diseased cells. In one experiment, scientists studied how membranes of various shapes can pass through and delay human embryonic kidney cells (HEK 293).

The invention will be the first domestic device of its kind to be mass-produced. It will be able to replace foreign, mainly German, analogues that Russian specialists are currently forced to use.

— Our device will also make a breakthrough in photonics. Currently, one of its problems is that various technologies and materials are used to produce emitters, receivers, and parts of photonic integrated circuits related to information processing. We can link all this together on a single chip using polymer fiber, which can be formed using a new lithograph. Currently, there are no domestic competitors in this field in the Russian market of devices, and the project promotes import substitution, since the market is dominated mainly by German models," said Danila Kolymagin.

Photonics is a branch of science that studies fundamental and applied aspects of working with optical signals. Currently, many innovative devices are being created based on them. In fact, this is an analog of electronics, in which photons are used instead of electrons. Lasers, fiber-optic networks, sensors and other equipment are created based on the principles of photonics. Scientists from all over the world are working on creating an optical computer that will significantly surpass electronic computers in its properties.

One of the main advantages of the new lithograph is the ability to work in 3D printer mode, which expands its capabilities. Ultrashort laser pulses of the visible range are used for lithography, which significantly reduces the cost of equipment and its maintenance. Optically transparent biocompatible photopolymers, which were specially created in collaboration with the Nizhny Novgorod Razuvaev Institute of Organometallic Chemistry of the Russian Academy of Sciences, are used as a material for 3D microstructures.

As another possible application in the field of physical research, the developers name the creation of phase masks. They consist of transparent materials, passing through which the light changes its amplitude-phase characteristics. Such masks can be used to encode information using light, form holograms, and metallics.

The project is currently in the final stage of development work. In April 2025, state interdepartmental acceptance tests will be conducted, based on the results of which a decision will be made on the acceptance of the device. It is expected that the development will be completed in August 2025, after which the lithograph will go into widespread production. Its main customers will be scientific centers and companies engaged in photonics and biophotonics.

Artificial organs and neural interfaces

The quality of biopolymer scaffolds plays a very important role in the creation of artificial organs, Ivan Pyanov, associate professor at the Institute of Biomedical Systems at the National Research University MIET, explained to Izvestia.

— The production of high-quality skeletons is necessary to create a competitive base for the development of biomedical engineering and artificial organs. Therefore, the new lithograph will be in demand for this purpose in cooperation with specialists in the field of 3D bioprinting, who use various scaffolds and matrices to fill them with stem cells. Such constructions are currently being tested in clinical trials and on laboratory animals. In the manufacture of the frame, the precision and porosity of the structure, as well as the type of biopolymer from which it is made, are very important," said the expert.

According to other experts, the new lithograph can also be used to create neural interfaces.

— Lithography allows you to create high-precision micro- and nanostructures, which is critical for reproducing the complex architecture of an object. This has great potential for different directions. For example, this technology can be used to develop neural interfaces, as well as organs on a chip," said Stanislav Petrov, Deputy Director of the Institute of Biomedical Engineering at NUST MISIS.

This area of research is quite important for science and industry, says Fyodor Kiselyov, a leading researcher at the Laboratory of Quantum Communications at ITMO University. The proposal to use this technology to connect integrated optical chips is particularly interesting. This can qualitatively improve the process of hybrid assembly of photonic integrated circuits. However, there remains a question about the speed of operation of this device, which in the end will affect the cost of development carried out with its help, the specialist concluded.

Переведено сервисом «Яндекс Переводчик»