- Статьи

- Science and technology

- A combustible stone: how during the war years gasoline was made solid, and turpentine was extracted from resin stumps

A combustible stone: how during the war years gasoline was made solid, and turpentine was extracted from resin stumps

During the Great Patriotic War, the supply of fuels and lubricants sometimes required ingenuity and non-standard approaches. Such solutions, for example, were the laying of temporary pipelines or the transportation of liquid fuel in a cured state. At the same time, fuel for military and civilian equipment was sometimes obtained from non-traditional sources. For example, the guerrillas produced turpentine from the resin of coniferous trees, which could sometimes be used to refuel fuel tanks. For more information, see the Izvestia article.

How fuel and lubricants were delivered during the war

Timely supply of fuel and lubricants is one of the keys to victory. However, during the Great Patriotic War, Soviet troops faced a shortage of fuel. These problems were often solved using non-standard methods.

— By 1940, 12 new oil refining plants had been built in the country, but they were only reaching their projected capacity. Therefore, by the beginning of the war, about 85% of all petroleum products were produced in the Caucasus. From here, fuel and lubricants were delivered to all consumers, including the military, by rail, tankers of the Caspian and Volga Shipping Companies, as well as by car," historian Yuri Minkevich told Izvestia.

In the summer of 1942, he added, during the German offensive on Stalingrad and the Caucasus, the supply of petroleum products by traditional routes became impossible. To solve the problem, railways were built as soon as possible from Dagestan to Astrakhan, as well as on the left bank of the Volga.

In addition, the railway tanks were towed afloat across the Caspian Sea. Moreover, from September 1942 to March 1943, this was the only way. They were transported via the Caspian Sea to Krasnovodsk (now Turkmenbashi, Turkmenistan), and then by a roundabout route through Ashgabat, Tashkent, Kzyl-Orda, Aktyubinsk to the Urals and Volga to secure the Stalingrad front. The length of the route increased by almost 3 thousand km. Fuel trains reached the fronts in 30-40 days.

How to get jet fuel and save fuel in the rear

According to the historian, there was also a problem with jet fuel. So, on the eve of the war, up to 85% of all oil at domestic refineries was processed using the direct race method, and fuel quality improvement technologies were at a low level. From one ton of oil, only 35 kg of high-octane gasoline brands demanded by aviation and only 3 kg of aviation oils were obtained.

— By the beginning of the war, the USSR oil industry was producing 10 types of aviation gasoline. The main brands were B-70 and B-74. The B-78 had the best anti-knock properties, but its share in production was only 7.8%. The problem was solved by adding additives based on ethyl liquid," explained Yuri Minkevich.

At the same time, he said, the American P-39 "Aerocobra" and British "Spitfires" that arrived under lend-Lease consumed only high-octane gasoline. They were supplied from the USA and the British refineries in Iran. Four sets of installations for oil refineries were also purchased under lend-lease. They were used in the construction of refineries in Kuibyshev, Guryev, Orsk and Krasnovodsk. The first 100-octane domestic gasoline began to be produced at the Kuibyshev refinery in September 1945.

According to the aviation historian of Yakutia Vasily Gogolev, alternative ways of obtaining jet fuel were being worked out in the management of the Baikal–Krasnoyarsk air route, one of the main routes for the supply of aircraft and equipment from the United States. Here it was proposed to extract fuel from boghead, coal from algae, deposits of which were discovered near the Olenek River. The author of the idea is the Yakut scientist Konstantin Kondakov. Resin was melted from boghead and divided into fractions. However, this idea was not realized during the war. Experimental production was launched after its completion, but due to the high cost, the project was closed.

— First of all, high-quality fuels were provided by the front and strategic facilities. Alternative energy sources were often resorted to in the rear. In particular, in Siberia and the Far East, gas-powered vehicles were widely used in logging and other facilities. They used wood as fuel," said Sergey Trofimenko, head of the Soldiers of the Fatherland branch of the Irkutsk Museum of History.

The specialist explained that the gas generator set was a metal column that was placed on the side of the truck or in the back. In it, wood fuel decomposed slowly under conditions of lack of oxygen and high temperatures. The resulting gas mixture was cleaned of impurities and fed into the engine. The advantage of such equipment was the cheapness of fuel, but at the same time the power plant's capacity dropped by 30-50%.

How the partisans got turpentine from coniferous trees

Turpentine workshops in the partisan detachments of Belarus and in the Bryansk region are another example of obtaining fuel from local resources, said Elena Mikhailova, head of the department of exposition, exhibition, scientific and educational work at the Partizanskaya Polyana memorial complex.

"In the summer of 1942, there were about 30 tanks and armored vehicles, both domestic and captured, in service with the Southern Bryansk Partisan Territory alone," she noted. — For this technique, the partisans made fuel in artisanal conditions. It was turpentine, which was obtained by distillation of resin stumps. Such installations are called "Minsk retorts" — according to their conditional place of origin.

The specialist explained that in the apparatuses, the raw materials were heated to 200 ° C for 12-18 hours. At the same time, a vapor-gas mixture was released from the resin, which passed through filters, was cleaned and cooled. As a result, the gas condensed and turned into a liquid — ready turpentine. The process lasted about four days.

In the difficult conditions of forest life, turpentine was used to lubricate weapons and equipment, as an antiseptic and medicine for the treatment of sciatica and rheumatism, she added. According to some evidence, it was also used for refueling cars. A part of the Minsk retort, which belonged to the Death to the German Occupiers detachment, is located on the territory of the Partizanskaya Polyana complex.

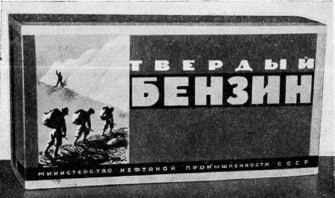

How "solid gasoline" was made

Non-standard solutions were also used to transport fuel, said historian Yuri Minkevich. In particular, gasoline was transported in a cured state. That is, in the form of small-cell briquettes, the cell walls consisted of a high-strength substance. The fuel inside could not leak through them.

The briquettes could have any shape, usually they weighed from 10 to 20 kg. The gasoline content in them was 93-96%. Fuel in this form could be stored in stacks at any site and even underwater. During transportation, fuel losses were less than 0.05%.

— To apply fuel, it was returned to a liquid state by destroying the solid shell. In particular, the Academy of Mechanization and Motorization of the Red Army developed a device for field conditions that was powered by human muscular strength. It had a capacity of 30 liters per hour and was designed for amphibious units and partisan detachments," the historian explained.

Widespread production of "solid gasoline" has not been established, although after the liberation of the Caucasus in 1943, a plant with a capacity of 20,000 tons of "solid gasoline" per year began to be built in Grozny, he added.

At the same time, Yuri Minkevich noted, pipelines were widely used for the first time during the war to deliver fuel and lubricants. One of the first experiments was obtained by providing gasoline to units of the 52nd Army at a bridgehead near the Volkhov River in March-April 1942.

Then, in June – July 1942, a long pipeline was laid along the bottom of Lake Ladoga for the first time in the history of military affairs. It took only 43 days to build it. The length (including land sections) was 29 km, and the capacity was up to 350 tons of fuel per day. This infrastructure operated for 20 months before the lifting of the siege of Leningrad in 1944. In total, more than 40 thousand tons of light oil products were supplied to the besieged city through the pipeline.

Переведено сервисом «Яндекс Переводчик»